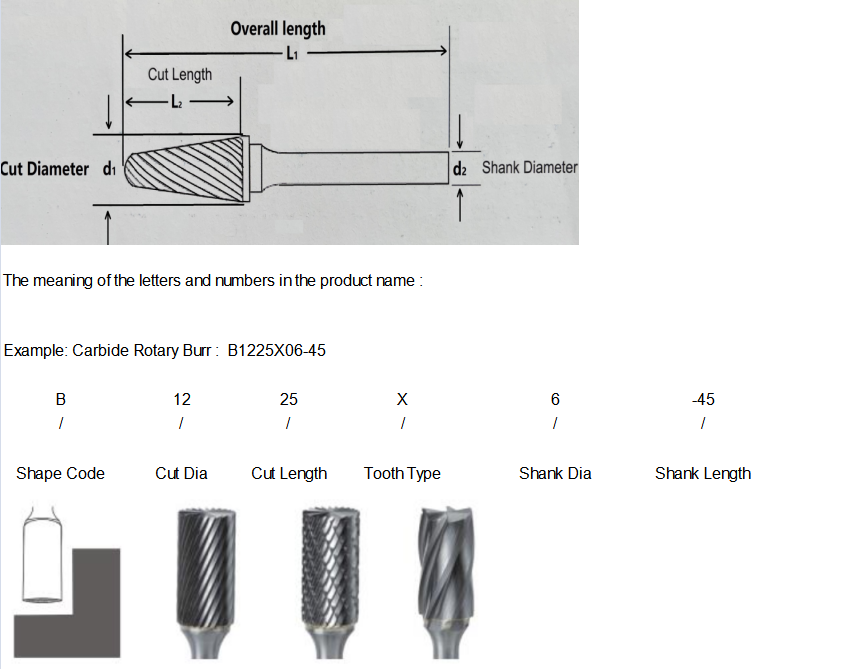

| Types of Cutting Edge | Images | Application |

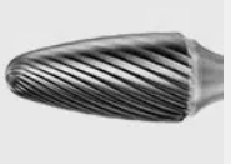

| Single Cut M |  | The standard single cutting head ,serrated shape is fine,and the surface finish is good,it is suitable for processing hardened steel with hardness HRC40-60 degrees,heat resistant alloy,nikel base alloy ,Cobalt based alloy,stainless steel,etc |

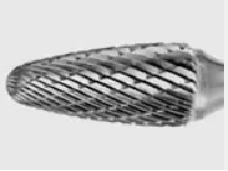

| Double Cut X |  | This double cutting shape has short chip and high surface finish, it is suitable for processing cast iron,cast steel ,steel with hardness less than HRC60,Nikel based alloy ,cobalt based alloy,austenitic stainless steel,titanium alloy,etc. |

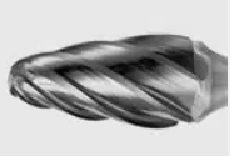

| Aluminium Cut W |  | The Aluminium cutting shape has a large chip pocket, a very sharp cutting edge and fast chip removal , it is suitable for processing aluminium ,aluminium alloy ,light metal ,non-ferrous metal,plastic ,hard rubber ,wood and so on |